The American Hospital Association released a report in February 2021, analyzing hospital revenue. This document predicts a collective loss for hospitals and healthcare systems.

The most optimistic scenario shows a $53 billion revenue decline. The report goes on to state that this loss could reach $122 billion due to several factors. These include ongoing partial patient volume recovery, slow vaccination rates, and cyclical COVID-19 surges.

The Kaufman Hall report addressed, among other problems, hospital supply chain issues. They predict a 13 percent increase in the cost of healthcare supplies. Materials managers must have solutions that optimize supply inventories. Keep reading to learn about the BlueQ Analytics solution.

Hospital Supply Chain Issues

The COVID-19 pandemic wrought unprecedented damage to the global healthcare supply chain. The demand increased when there were disruptions in device manufacturing and delivery operations. The FDA is now closely tracking the medical product supply chain.

They are watching for signs of future interruptions in the flow of devices and supplies. In fact, the FDA is currently working with manufacturers and stakeholders to reduce and prevent risks. By fostering this collaboration, the FDA hopes to avoid further negative impacts on healthcare providers and patients.

Unfortunately, the healthcare supply chain continues to struggle after more than a year of the pandemic. The demand for personal protective equipment (PPE) and other supplies remains high.

Exam Gloves

Experts predict that glove availability will remain in short supply until 2023. The global demand for nitrile gloves is outpacing the production capacity. There is a scarce supply of the raw materials needed to make these gloves.

Experts predict that glove availability will remain in short supply until 2023. The global demand for nitrile gloves is outpacing the production capacity. There is a scarce supply of the raw materials needed to make these gloves.

When quarantines went into effect, shipping ports closed or faced delays. This contributed to the supply shortage during a time when the demand doubled. In fact, many hospitals rated glove access as their second greatest challenge behind staffing.

N95 Masks

The initial surge in the demand for N95 masks overwhelmed most hospitals. On average, healthcare systems had less than a 30-day supply of N95 masks on hand.

The initial surge in the demand for N95 masks overwhelmed most hospitals. On average, healthcare systems had less than a 30-day supply of N95 masks on hand.

Today, hospitals have been able to increase their stock of these masks. Yet, many healthcare providers had to re-use single-use masks to “stretch the supply.”

Surgical Masks

Hospitals also experienced a mask shortage when the pandemic hit. The demand for surgical and isolation masks suddenly tripled.

Hospitals also experienced a mask shortage when the pandemic hit. The demand for surgical and isolation masks suddenly tripled.

They were forced to institute conservation measures to try and keep up with the need. Today, hospitals have greatly increased their mask supply which also means increased expenses.

Isolation Gowns

In April 2020, the top PPE shortage was isolation gowns. At the time, hospitals only had about a 20-day supply on hand. With the demand doubling, facilities faced large expenses to try and keep pace.

In April 2020, the top PPE shortage was isolation gowns. At the time, hospitals only had about a 20-day supply on hand. With the demand doubling, facilities faced large expenses to try and keep pace.

Healthcare providers will continue to experience supply chain shortages due to COVID-19. The recent blockage of the Suez Canal caused another disruption in supply delivery. The U.S. and the global market are also still facing manufacturing, labor, and logistics issues.

Using Analytics to Bolster Your Hospital Supply Chain

Data analytics using artificial intelligence (AI) offer valuable tools. The increase in manufacturer and distributor data transparency helps align resources. All parties can work together to address current and future demands.

Hospital supply chains must focus on data and analytics to drive inventory planning. The pandemic taught the healthcare industry about the importance of incorporating redundancy. Supply chain leaders have needed to learn the balance of establishing surplus storage in preparation for future crises while balancing current demand.

This poses a difficult challenge. What items and volumes are needed to prepare for the unknown? PPE will always be essential to protect the staff. But a future crisis may also demand many different medical supplies.

This is where data analytics can assist with planning and preparation. It provides evidence to evaluate changing trends. This helps facilities navigate previously unforeseen challenges with the supply chain. BlueBin has been providing the transformational standard of work through Kanban and Analytics to hospitals to be prepared for every contingency while maintaining the most optimized daily supply chain for over 10 years.

BlueQ Analytics

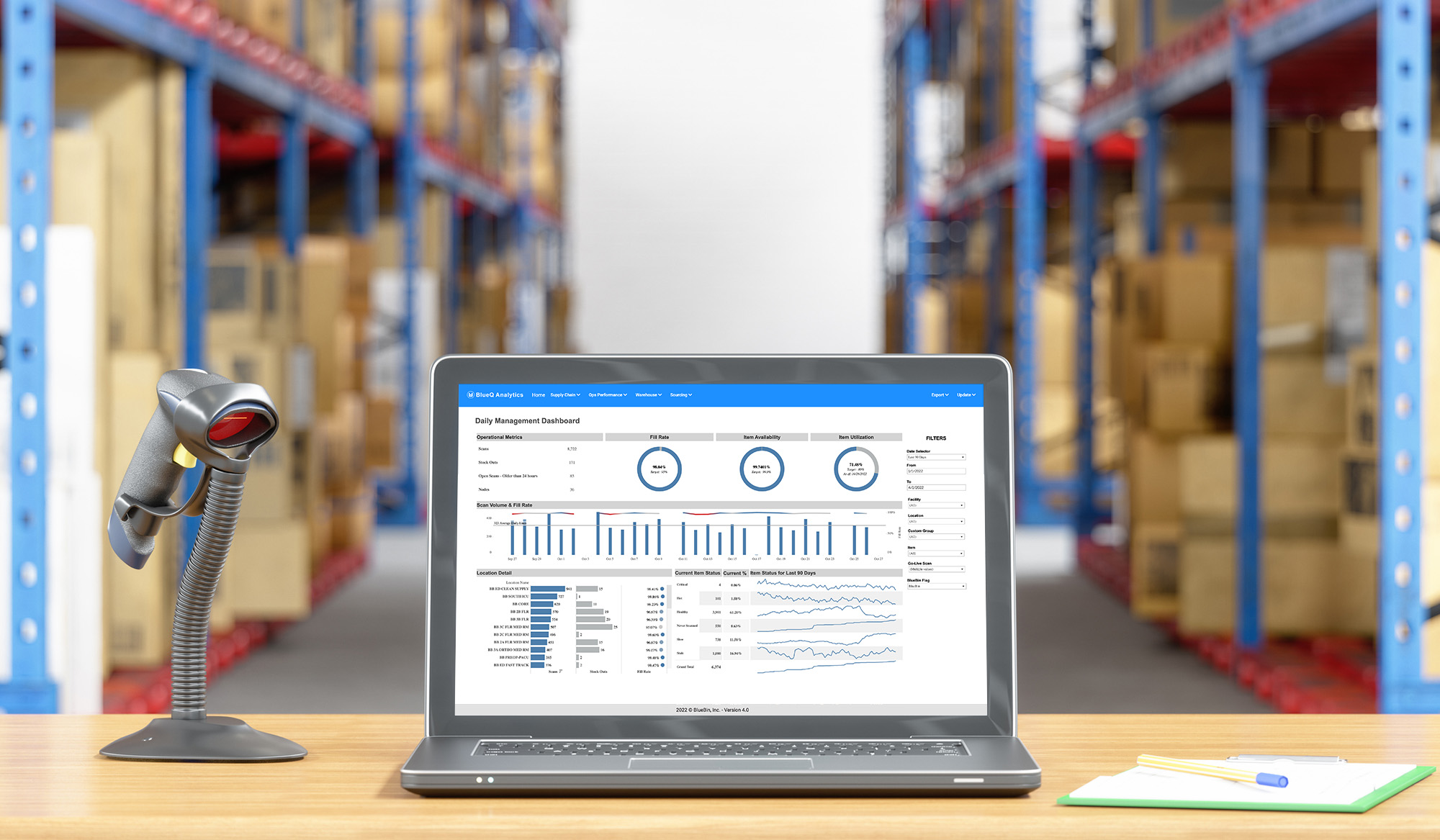

BlueBin provides complete supply chain visibility via BlueQ Analytics. Robust and easy-to-use reporting gives supply chain and clinical leadership the critical data when needed to make rapid decisions. These predictive analytics and actionable insights ensure a reliable and efficient system for maintaining all inventory.

Being very flexible, the materials team can use a mobile device, scanner, or tablet for BlueQ SmartScan. This allows the team to view aggregate spend and productivity data to improve efficiency. Time and labor management tools show which employees are performing supply management activities, and thoughtfully distribute your labor load. The device also tracks activity time management and efficiency of item routing.

The flexibility of BlueQ SmartScan provides the ability to manage many POU systems, including existing Par Carts and 2-Bin Kanban systems.

It accesses established standard operating procedures, serving to revolutionize hospital supply chains. BlueBin and BlueQ Analytics also offer SOPs (standard operating procedures) that assist with DIY Kanban implementations.

BlueQ Analytics and SmartScan tools are by far the best solution to help track and make inventory management decisions.

- Daily huddle board

- Dashboard reporting to assess fast-moving or critical items

- Overall health telemetry

- Heat map to assess the supply room health

- Alerts for any items that aren’t being used, slow-moving, or are about to expire

- A view of the rate of item usage

- An optimized perpetual inventory

- Aggregate spend data and supply room sizing tools

- Performance reports for buyers, suppliers, and spend

Is It Time to Move to a Cutting-Edge Supply Management System?

The world is still struggling with the pandemic’s hospital supply chain disruptions. It’s time to reduce your material management stress and strain. BlueBin has the solutions available to meet your needs today.

Our mission is to dramatically improve healthcare. We strive to accomplish this by adding value to supply chain processes. This gives healthcare providers the supplies they need when they need them. This also gives clinicians all of their time back to spend on patient care, what they were trained to do.

BlueBin fuses cutting-edge technology with efficient methods and lean principles. This creates a standardized operating system to manage medical supplies in all areas of the facility, or system. The spending reports give you the resources you need to offer quality patient and family care.

Contact us today to learn more about our solutions.