In an era of geopolitical shifts, cyberattacks, and countless unpredictable disruptions, healthcare supply chain leaders are under immense pressure. The COVID-19 pandemic exposed critical vulnerabilities—shortages of PPE, medications, and critical medical products brought operations to a breaking point. But disruptions aren’t limited to global crises. Sometimes, they strike without warning, as I experienced firsthand.

A Real-Life Scenario

As the interim VP of Supply Chain at a prestigious community hospital, I was immersed in the hundreds of emails I received daily when an unusual quietness suddenly eclipsed the usual office hum. Moments later, staff from various departments began stepping out into the hallways, confusion etched on their faces. Within an hour, our IT team determined we were facing an enterprise-wide IT shutdown—a suspected ransomware attack.

Digital systems went offline, including all Internet of Things (IoT) and Internet of Medical Things (IoMT) devices. The ripple effects were immediate and severe. We swiftly established a Crisis Command Center and reverted to paper-based operations across patient care and administration, causing drastic slowdowns in care delivery, supply chain logistics, and communication. To navigate this, we dusted off our old internal pneumatic tube system for document transfers—many younger staff members, who had never seen such a system in action, were shocked at how seamlessly healthcare veterans adapted to analog processes.

The ransom payment of over $11 million was burdensome but necessary to regain functionality. Coordinating system restoration among vendors—competitors who had never worked together—highlighted glaring vulnerabilities in our preparedness strategy. This incident manifested two powerful lessons: resilience isn’t theoretical—it’s survival, and, unfortunately, paying the ransom is the current recommendation when facing a ransomware attack.

Defining Supply Chain Resilience in Healthcare

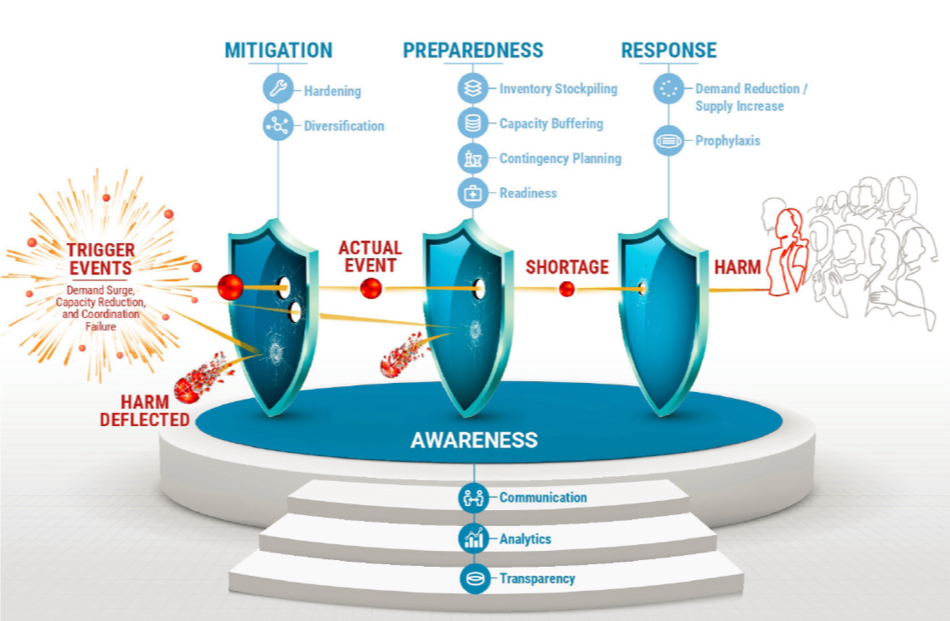

Supply chain resilience in healthcare refers to the ability to anticipate, prepare for, respond to, and recover from disruptions while maintaining the continuous flow of critical goods and services. It’s about more than just surviving a crisis—it’s about minimizing financial losses, ensuring patient safety, and sustaining operational stability through:

- Flexibility & Adaptability – Adjusting sourcing, inventory, and logistics in real time.

- Robust Risk Management – Proactively identifying and mitigating vulnerabilities (like cyber threats).

- Strategic Partnerships – Diversifying suppliers and fostering collaborative relationships (even among competitors in a crisis).

- Technology & Innovation – Leveraging AI, cloud-based systems, and digital twins for smarter decision-making— before disaster strikes.

Key Lessons for Building a Resilient Healthcare Supply Chain

- Prepare for the Unthinkable—Because It Will Happen – Conduct tabletop exercises for cyberattacks, natural disasters, and supply shortages. Ensure staff know manual workarounds.

- Diversify Suppliers—Don’t Put All Your Eggs in One Basket – Conduct a supplier risk assessment and build redundancy into your sourcing strategy.

- Balance Inventory: Just-in-Time vs. Just-in-Case – Implement strategic stockpiles for high-risk items while optimizing JIT for stable supplies.

- Strengthen Financial Resilience – Disruptions are expensive. When costs rise (and you can’t pass them to patients), explore alternative revenue streams and cost-saving measures to protect margins.

- Invest in Low-Tech Backups – Analog redundancies (paper records, manual processes) are just as critical as digital systems.

- Vendor Coordination Is Non-Negotiable – Pre-establish collaboration protocols with key suppliers, even rivals.

- Embrace VUCA Principles – The healthcare landscape is defined by Volatility, Uncertainty, Complexity, and Ambiguity (VUCA). Scenario planning and adaptive training prepare teams for the unexpected.

- Invest in Technology & Visibility – Real-time tracking prevents stockouts and overstocking. AI-driven forecasting improves demand planning. Digital twins simulate disruptions before they happen.

- Train for Adaptability – Supply shortages demand creative problem-solving—like substituting butterfly needles with straight needles when necessary. Ensure staff are trained to pivot quickly.

- Cyber Resilience Is Supply Chain Resilience – Audit IT vulnerabilities and segment networks to limit breach impacts.

The Bottom Line: Resilience = Survival + Competitive Advantage

A resilient supply chain isn’t just about avoiding disasters—it’s about building trust with stakeholders, improving patient outcomes, and safeguarding financial stability. The next disruption isn’t a matter of if but when. The time to act is now.

Article Series: "Building Unbreakable Healthcare Supply Chains"

- What is Healthcare Supply Chain Resilience?

- Why Consistent Supply Chain Resilience Assessments Are Vital

- Financial Resilience—Protecting Your Healthcare Organizations from Cost Shocks

- Supplier Diversification—Why Relying on One Vendor Isn’t Wise

- Technology & AI—The Future of Resilient Healthcare Supply Chains

- Climate Change & Supply Chain Risk—What Healthcare Organizations Must Do Now

- Staff Training & Culture—The Human Side of Supply Chain Resilience

- The ROI of Resilience—How Prepared Healthcare Organizations Save Millions